🕑 Reading time: 1 minute

Mix design of high strength concrete is influenced by properties of cement, sand aggregates & water-cement ratio have compressive strength above 40 MPa. To achieve high strength, it is necessary to use lowest possible water-cement ratio, which invariably affects the workability of the mix and necessitates the use of special vibration techniques for proper compaction. In the present state of art, a concrete with a desired 28 day compressive strength of upto 70 MPa can be made with suitably proportioning the ingredients using normal vibration techniques for compacting the concrete mix.

Table – 2: Aggregate cement ratio (by weight) required to give four degrees of workability with different water –cement ratios using rapid hardening cement

Table – 2: Aggregate cement ratio (by weight) required to give four degrees of workability with different water –cement ratios using rapid hardening cement

Mix Design of High Strength Concrete -Procedure

- The mean design strength is obtained by applying suitable control factors to the specified minimum strength.

- For a given type of cement and aggregates used, the reference number corresponding to the design strength at a particular age is interpolated from figure 1 to 4.

- The water-cement ratio to achieve the required workability and corresponding to the reference number is obtained from figure 5 for aggregates with maximum sizes of 20mm and 10mm.

- The aggregate-cement ratio to give the desired workability with the known water cement is obtained by absolute volume method.

- Batch quantities are worked out after adjustments for moisture content in the aggregates.

Fig.1: Relation between compressive strength and reference number (Erntroy and Shacklock)

Fig.1: Relation between compressive strength and reference number (Erntroy and Shacklock)

Fig-2: between compressive strength and reference number (Erntroy and Shacklock)

Fig-2: between compressive strength and reference number (Erntroy and Shacklock)

Fig-3: Relation between compressive strength and reference number (Erntroy and Shacklock)

Fig-3: Relation between compressive strength and reference number (Erntroy and Shacklock)

Fig-4: Relation between compressive strength and reference number (Erntroy and Shacklock)

Fig-4: Relation between compressive strength and reference number (Erntroy and Shacklock)

Fig-5: Relation between water-cement ratio and Reference Number

Fig-5: Relation between water-cement ratio and Reference Number

Fig-6: Combining of Fine aggregates and Coarse aggregates

Table – 3: Batch Quantities per cubic metre of concrete

Fig-6: Combining of Fine aggregates and Coarse aggregates

Table – 3: Batch Quantities per cubic metre of concrete

High Strength Concrete Mix Design Example

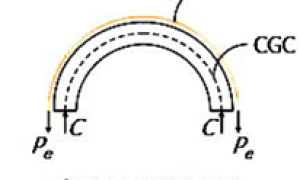

Design a high strength concrete for use in the production of precast prestressed concrete to suit the following requirements: Specified 28-day works cube strength = 50 MPa Very good degree of control; control factor = 0.80 Degree of workability = very low Type of cement = ordinary Portland cement Type of coarse aggregate = crushed granite (angular) of maximum size 10mm. Type of fine aggregate = natural sand Specific gravity of sand = 2.60 Specific gravity of cement = 3.15 Specific gravity of coarse aggregates = 2.50 Fine and coarse aggregates contain 5 and 1 percent moisture respectively and have grading characteristics as detailed as follows:| IS sieve size | Percentage Passing | |

| Coarse aggregate | Fine aggregate | |

| 20mm | 100 | - |

| 10mm | 96 | 100 |

| 4.75mm | 8 | 98 |

| 2.36mm | - | 80 |

| 1.18mm | - | 65 |

| 600 microns | - | 50 |

| 300 microns | - | 10 |

| 150 microns | - | 0 |